Biomechanical weaving: Why 2025 Changes Everything for Wearables

It Took Us 5 Years to Realize the Intelligence Wasn’t in the Chip — It Was in the Weave.

A five-year evolution: from very little references on functional weaving patterns to a booming ecosystem of smart textile research, production, and real-world applications.

Back in 2020, there were almost no references to sophisticated weaving patterns providing real functional enhancements in smart textiles for the human body. Today, this field is growing — both scientifically and industrially — with a clear shift from material innovation to architectural intelligence within fabrics themselves.

Smart Textiles Are Growing Up.

Recent reviews show that smart textiles now integrate functionalities at all levels — fiber, yarn, and fabric — with biosensing, biomechanical monitoring, and energy harvesting as leading applications. Flexible electronics and textile manufacturing have merged, allowing mass production of multifunctional fabrics where sensors, stretchable conductors, and miniature power sources are embedded seamlessly — without compromising comfort or washability.

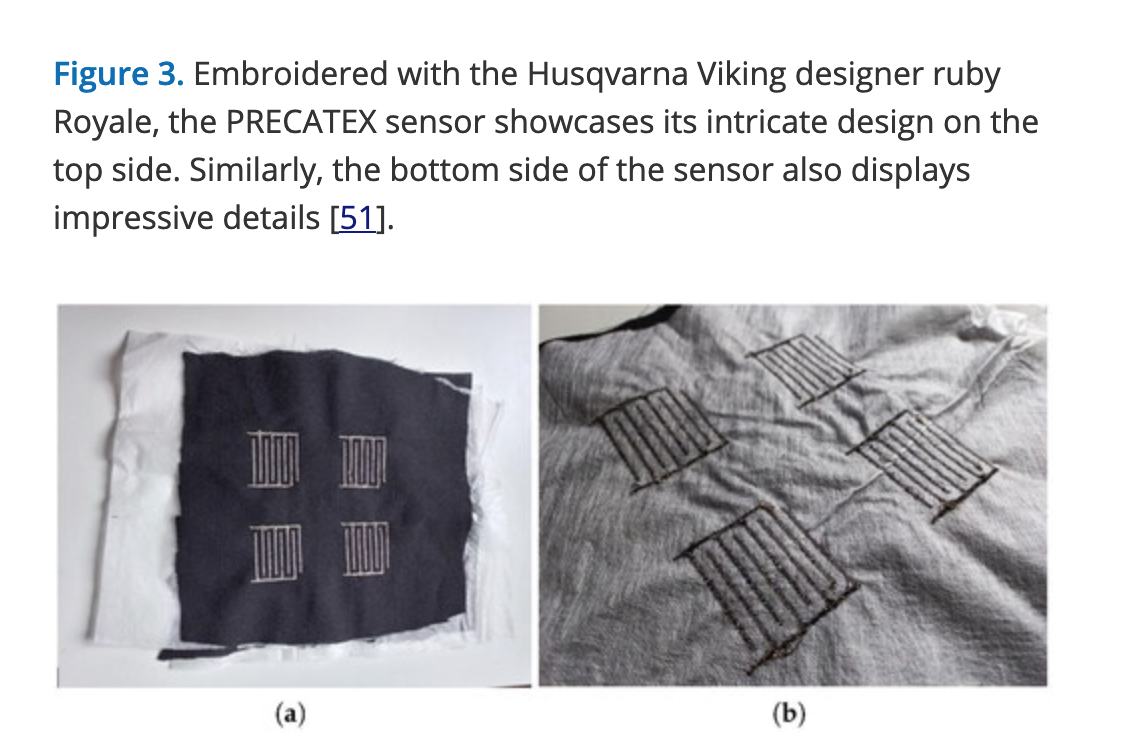

The textile structure, including weaving patterns, now plays a crucial role in optimizing sensor placement, signal quality, durability, and user comfort — one of the most actively explored areas in research labs worldwide.

The global smart textile market is expected to surge from $6.61 billion in 2025 to over $67 billion by 2035, reflecting a CAGR above 26%. This growth is driven not only by new materials, but by advances in textile engineering — where pattern design itself defines sensing precision, comfort, and energy efficiency.

2D/3D textile architectures research centers to watch

In 2025, specialized research centers are investigating how 2D/3D textile architectures enable real wearable functionalities — not just new fibers or coatings.

-

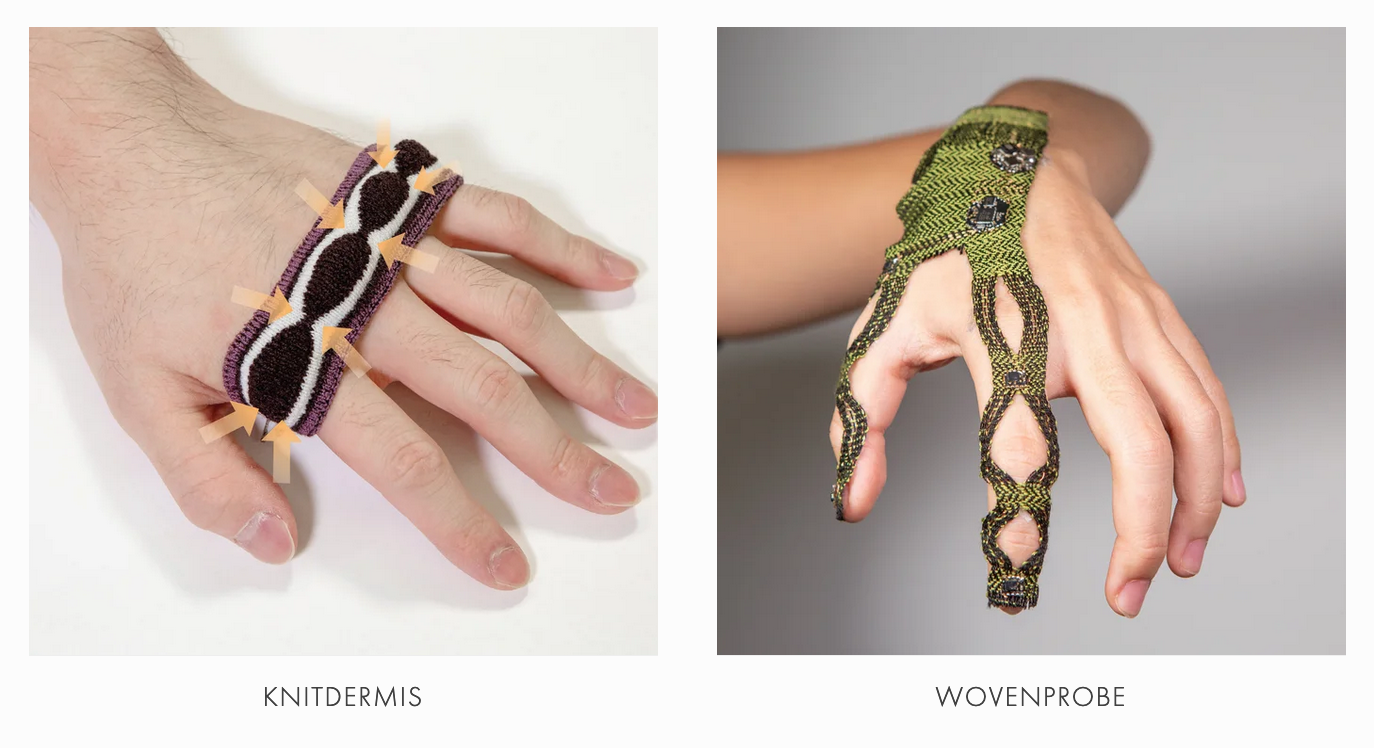

Cornell Hybrid Body Lab: uses a Jacquard digital loom (TC2) to design 3D woven structures integrating electrochemical sensors in sweat zones. Their BioWeave platform explores how textile architecture improves signal capture, data accuracy, and garment integration — balancing anatomical placement, comfort, and data quality.

Cornell Hybrid Body Lab →

-

2025 Academic Review on Textile Sensors and 3D/Bidirectional Weaves: documents weaving strategies like bidirectional and 3D orthogonal structures and binary-yarn patterns that increase contact area, triboelectric sensitivity, and energy harvesting.

Read review →

-

Weaving Pattern Impact on Functional Properties: analyzes how fabric architecture affects interfacial and functional properties, offering design guidelines for future functional textiles and wearable systems.

ScienceDirect study → -

Eurecat Functional Fabrics Unit (Spain): focuses on integration, scalability, and cost optimization to bridge laboratory innovation and real-world production.

Eurecat → -

DOST-PTRI Handloom Weaving Center (Philippines): a 2025 initiative merging traditional handloom and digital design for rapid prototyping of functional textile architectures.

DOST-PTRI →

Highlights: 2025 Textile Innovations

-

Ultrathin textile musclesdeveloped in South Korea mimic human muscle structure, assisting movement without heavy motors.

Read more →

-

Resilient, flexible fabrics without electronics transmit tactile signals, regulate temperature, and communicate through fluidic logic — using air pressure instead of circuits.

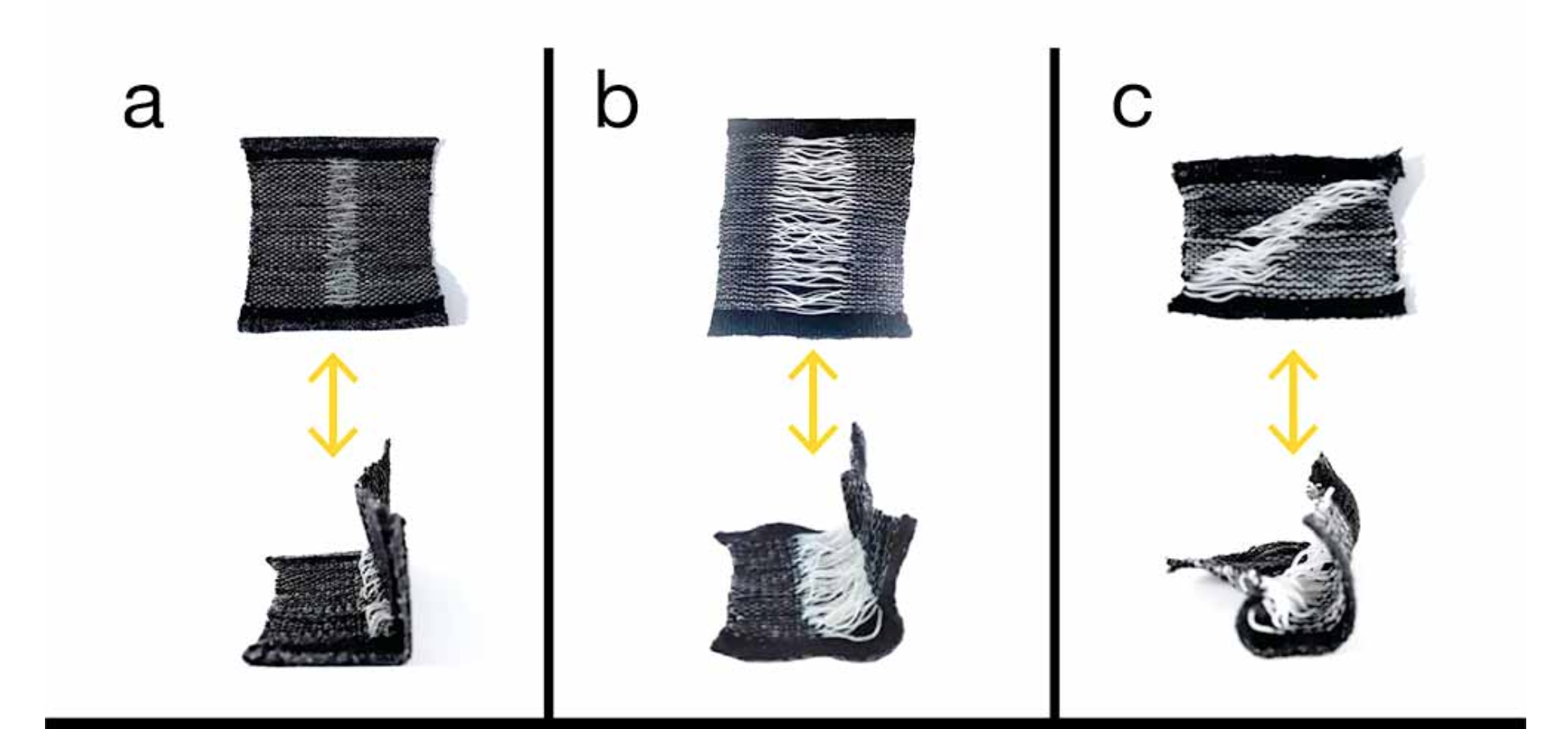

Learn more → - Active smart textiles with shape-memory elastomers and dynamic color/shape changes offer adaptive comfort and energy storage capabilities.

- Non-electronic tactile communication garments use pressure-based signaling to enhance human–machine communication in environments where screens are impractical.

-

Shape changing textiles

MIT FibeRobo temperature-regulating fibers →

Summary

2025 marks a decisive shift: the missing link between materials and real-world applications is finally being addressed.

The intelligence is no longer in the chip — it’s in the weave.

We are moving from “smart materials” to smart architectures — fabrics that think, sense, and act through their weaving logic. The convergence of textile engineering, digital weaving, and material science is redefining wearables — from reactive clothing to biomechanical intelligence.